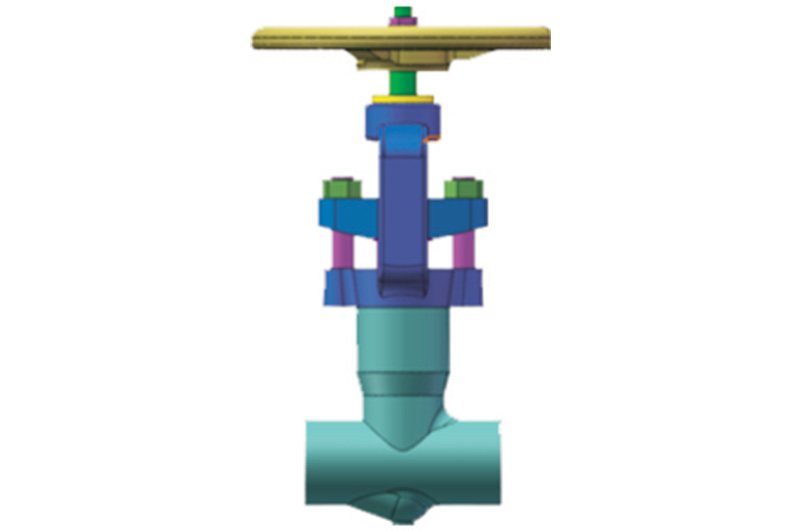

The valve plays an important role in the cutting and throttling of the medium in the pipeline in which it is located. The shut-off valve is an extremely important type of shut-off valve. The seal is applied by applying torque to the valve stem, and the valve stem is oriented in the axial direction. The valve disc applies pressure so that the disc sealing surface fits snugly against the seat sealing surface, preventing the medium from leaking along the gap between the sealing faces.

The seal pair of Bonnetless Globe Valves consists of a disc seal face and a seat seal face that moves the flap vertically along the centerline of the seat. During the opening and closing process of the shut-off valve, the opening height is small, the flow rate is easy to adjust, and the manufacturing and maintenance are convenient, and the pressure is applicable to a wide range.

Compared to another commonly used cut-off valve in industrial production, the Bonnetless Globe Valves are structurally simpler than the ones, making them easier to manufacture and repair. In terms of service life, the sealing surface of the shut-off valve is not easy to wear and scratch, and there is no relative sliding between the valve flap and the sealing surface during the valve opening and closing process, so the wear and scratch on the sealing surface are small, so the sealing is improved. The service life stop valve of the auxiliary service has a small valve stroke during the full-closed process, and its height is relatively small compared to the alarm valve.

For our Wholesale Globe Valve, Gate Valve and other valves, contact us, you can learn more about the valve.

Previous: Seven Uses Of Instrument Valves